Efficiency of star - modularization structure tunnel dryer H1900 - (S)/H1400 - (S)/H800 - (S)

Introduction:

Hanswell star of efficiency, modularization structure tunnel dryer - suitable for mass production printing plant, drying speed and good effect, the operation is convenient.Solve the condition of the traditional oven time-consuming inefficient, is the ideal equipment of modern printing plant for mass production.

Parameter:

Model block | 1S | 2S | 3S | 4S | 5S | 6S | 7S | 8S | 9S | 10S | |||

L | H1900 | 3500 mm | 4500 mm | 5500 mm | 6500 mm | 7500 mm | 8500 mm | 9500 mm | 10500 mm | 11500 mm | 12500 mm | ||

H1400 | |||||||||||||

H800 | 3000 mm | 4000 mm | 5000 mm | 6000 mm | 7000 mm | 8000 mm | 9000 mm | 10000 mm | 11000 mm | 12000 mm | |||

W | H1900 | 2350mm | |||||||||||

H1400 | 1780mm | ||||||||||||

H800 | 1180mm | ||||||||||||

H | H1900 | 1200mm | |||||||||||

H1400 | 1100mm | ||||||||||||

H800 | 1100mm | ||||||||||||

Net (W) | H1900 | 1900mm | |||||||||||

H1400 | 1400mm | ||||||||||||

H800 | 800mm | ||||||||||||

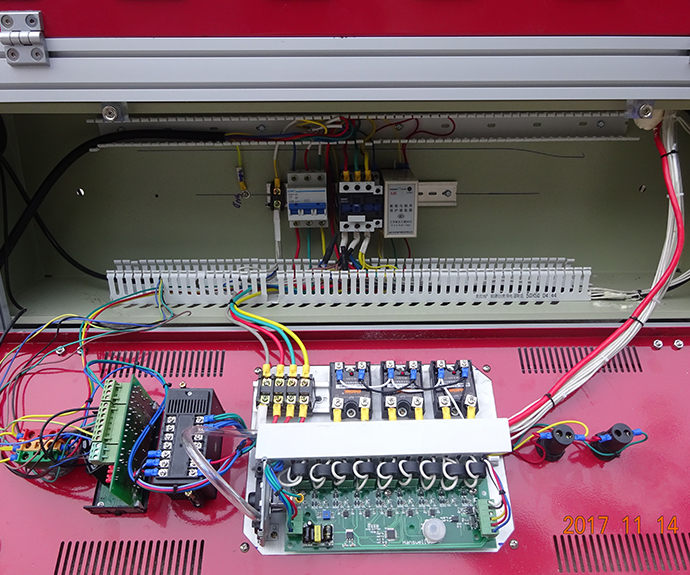

power supply | 380V three-phase five-wire / single-phase 220V | ||||||||||||

power kw | H1900 | 15 | 30 | 45 | 60 | 75 | 90 | 105 | 120 | 135 | 150 | ||

H1400 | 11 | 22 | 33 | 44 | 55 | 66 | 77 | 88 | 99 | 110 | |||

H800 | 8 | 16 | 24 | 32 | 40 | 48 | 56 | 64 | 72 | 80 | |||

Model features:

1, carefully study the mature control system for many years, high control precision, human nature is strong, the operation is simple to understand.According to the requirements of autonomous set temperature, power, speed of net belt, can adapt to different areas, different climate production conditions.Can be set in room temperature to 200 degrees.

2, equipment, the overall design is reasonable, the heat preservation performance is strong, less heat loss, less power consumption.

3, each box has an independent hot air circulation system, to ensure that the air in the cabinet in high speed circulation, eliminate the possibility of heat accumulation, the temperature of each part of the uniform, guarantee of the same products and effect;High-speed hot air circulation, increase the heat permeability of fabrics, speed up drying effect.

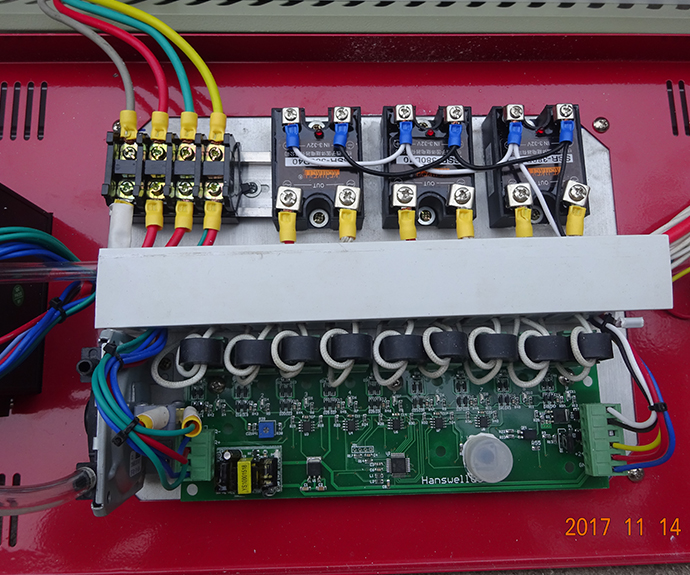

4, with international leading level of the fault automatic detection system, timely detection of failure of tubes, and blockage of the filter, and display the tube failure part, avoid replacing tubes need to screen them one by one;Simple troubleshooting, no professionals.

5, high efficiency and energy saving radiation tubes, imported stainless steel reflector, the use of heat energy with high efficiency.

6, casing material, laser cutting, teflon high temperature resistant net belt, roller, imported temperature measuring device, ensure the most efficient operation.

7, the equipment work smooth operation, quiet, safe and simple maintenance.

Advantages: quick drying, good effect, simple operation, energy conservation, environmental protection, excellent performance, powerful, durable, low maintenance rate, energy saving save electricity above 30%.

Fuselage shell: fine steel material to make a hard and durable of the fuselage, the whole body of the lacquer that bake to imported cars chassis not to drop paint, does not rust, easy cleaning, beautiful appearance design and easy!

Note: special dimensions and functions can be customized according to customer's requirement!